|

Heat exchanger for boiler, heavy fuel oil system, heat water systems,.. A boiler is a closed vessel in which water or other fluid is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications.

OVERVIEW:

- Materials: The pressure vessel in a boiler is usually made of steel (or alloy steel), or historically of wrought iron. Stainless steel is virtually prohibited (by the ASME Boiler Code) for use in wetted parts of modern boilers, but is used often in superheater sections that will not be exposed to liquid boiler water. In live steam models, copper or brass is often used because it is more easily fabricated in smaller size boilers. Historically, copper was often used for fireboxes (particularly for steam locomotives), because of its better formability and higher thermal conductivity; however, in more recent times, the high price of copper often makes this an uneconomic choice and cheaper substitutes (such as steel) are used instead.

For much of the Victorian "age of steam", the only material used for boilermaking was the highest grade of wrought iron, with assembly by rivetting. This iron was often obtained from specialist ironworks, such as at Cleator Moor (UK), noted for the high quality of their rolled plate and its suitability for high-reliability use in critical applications, such as high-pressure boilers. In the 20th century, design practice instead moved towards the use of steel, which is stronger and cheaper, with welded construction, which is quicker and requires less labour.

Cast iron may be used for the heating vessel of domestic water heaters. Although such heaters are usually termed "boilers" in some countries, their purpose is usually to produce hot water, not steam, and so they run at low pressure and try to avoid actual boiling. The brittleness of cast iron makes it impractical for high pressure steam boilers.

- Fuel: The source of heat for a boiler is combustion of any of several fuels, such as wood, coal, oil, or natural gas. Electric steam boilers use resistance- or immersion-type heating elements. Nuclear fission is also used as a heat source for generating steam. Heat recovery steam generators (HRSGs) use the heat rejected from other processes such as gas turbines.

- Configurations: Boilers can be classified into the following configurations:

* "Pot boiler" or "Haycock boiler": a primitive "kettle" where a fire heats a partially-filled water container from below. 18th century Haycock boilers generally produced and stored large volumes of very low-pressure steam, often hardly above that of the atmosphere. These could burn wood or most often, coal. Efficiency was very low.

* Fire-tube boiler. Here, water partially fills a boiler barrel with a small volume left above to accommodate the steam (steam space). This is the type of boiler used in nearly all steam locomotives. The heat source is inside a furnace or firebox that has to be kept permanently surrounded by the water in order to maintain the temperature of the heating surface just below boiling point. The furnace can be situated at one end of a fire-tube which lengthens the path of the hot gases, thus augmenting the heating surface which can be further increased by making the gases reverse direction through a second parallel tube or a bundle of multiple tubes (two-pass or return flue boiler); alternatively the gases may be taken along the sides and then beneath the boiler through flues (3-pass boiler). In the case of a locomotive-type boiler, a boiler barrel extends from the firebox and the hot gases pass through a bundle of fire tubes inside the barrel which greatly increase the heating surface compared to a single tube and further improve heat transfer. Fire-tube boilers usually have a comparatively low rate of steam production, but high steam storage capacity. Fire-tube boilers mostly burn solid fuels, but are readily adaptable to those of the liquid or gas variety.

* Water-tube boiler: In this type,the water tubes are arranged inside a furnace in a number of possible configurations: often the water tubes connect large drums, the lower ones containing water and the upper ones, steam and water; in other cases, such as a monotube boiler, water is circulated by a pump through a succession of coils. This type generally gives high steam production rates, but less storage capacity than the above. Water tube boilers can be designed to exploit any heat source and are generally preferred in high pressure applications since the high pressure water/steam is contained within small diameter pipes which can withstand the pressure with a thinner wall.

* Flash boiler : A specialized type of water-tube boiler.

Fire-tube boiler with Water-tube firebox. Sometimes the two above types have been combined in the following manner: the firebox contains an assembly of water tubes, called thermic siphons. The gases then pass through a conventional firetube boiler. Water-tube fireboxes were installed in many Hungarian locomotives, but have met with little success in other countries.

* Sectional boiler: In a cast iron sectional boiler, sometimes called a "pork chop boiler" the water is contained inside cast iron sections. These sections are assembled on site to create the finished boiler.

- Safety: Historically, boilers were a source of many serious injuries and property destruction due to poorly understood engineering principles. Thin and brittle metal shells can rupture, while poorly welded or riveted seams could open up, leading to a violent eruption of the pressurized steam. When water is converted to steam it expands in volume over 1,000 times and travels a down a steam pipes at over 100 kilometres/hr. Because of this steam is a great way of moving energy and heat around a site from a central boiler house to where it is needed, but without the right boiler feed water treatment, a steam-raising plant will suffer from scale formation and corrosion. At best, this increases energy costs and can lead to poor quality steam, reduced efficiency, shorter plant life and an operation which is unreliable. At worst, it can lead to catastrophic failure and loss of life. Collapsed or dislodged boiler tubes could also spray scalding-hot steam and smoke out of the air intake and firing chute, injuring the firemen who loaded coal into the fire chamber. Extremely large boilers providing hundreds of horsepower to operate factories could demolish entire buildings.

A boiler that has a loss of feed water and is permitted to boil dry can be extremely dangerous. If feed water is then sent into the empty boiler, the small cascade of incoming water instantly boils on contact with the superheated metal shell and leads to a violent explosion that cannot be controlled even by safety steam valves. Draining of the boiler could also occur if a leak occurred in the steam supply lines that was larger than the make-up water supply could replace. The Hartford Loop was invented in 1919 by the Hartford Steam Boiler and Insurance Company as a method to help prevent this condition from occurring, and thereby reduce their insurance claims.

- Superheated steam boilers: A superheated boiler on a steam locomotive.

Most boilers produce steam to be used at saturation temperature; that is, saturated steam. Superheated steam boilers vaporize the water and then further heat the steam in a superheater. This provides steam at much higher temperature, but can decrease the overall thermal efficiency of the steam generating plant because the higher steam temperature requires a higher flue gas exhaust temperature. There are several ways to circumvent this problem, typically by providing an economizer that heats the feed water, a combustion air heater in the hot flue gas exhaust path, or both.

There are advantages to superheated steam that may, and often will, increase overall efficiency of both steam generation and its utilisation: gains in input temperature to a turbine should outweigh any cost in additional boiler complication and expense. There may also be practical limitations in using wet steam, as entrained condensation droplets will damage turbine blades.

Superheated steam presents unique safety concerns because, if any system component fails and allows steam to escape, the high pressure and temperature can cause serious, instantaneous harm to anyone in its path. Since the escaping steam will initially be completely superheated vapor, detection can be difficult, although the intense heat and sound from such a leak clearly indicates its presence.

Superheater operation is similar to that of the coils on an air conditioning unit, although for a different purpose. The steam piping is directed through the flue gas path in the boiler furnace. The temperature in this area is typically between 1300–1600 degrees Celsius (2372–2912 °F). Some superheaters are radiant type; that is, they absorb heat by radiation. Others are convection type, absorbing heat from a fluid. Some are a combination of the two types.

Through either method, the extreme heat in the flue gas path will also heat the superheater steam piping and the steam within. While the temperature of the steam in the superheater rises, the pressure of the steam does not: the turbine or moving pistons offer a continuously expanding space and the pressure remains the same as that of the boiler. Almost all steam superheater system designs remove droplets entrained in the steam to prevent damage to the turbine blading and associated piping.

- Supercritical steam generator: Supercritical steam generators are frequently used for the production of electric power. They operate at supercritical pressure. In contrast to a "subcritical boiler", a supercritical steam generator operates at such a high pressure (over 3,200 psi/22.06 MPa or 3,200 psi/220.6 bar) that actual boiling ceases to occur, the boiler has no liquid water - steam separation. There is no generation of steam bubbles within the water, because the pressure is above the critical pressure at which steam bubbles can form. It passes below the critical point as it does work in a high pressure turbine and enters the generator's condenser. This results in slightly less fuel use and therefore less greenhouse gas production. The term "boiler" should not be used for a supercritical pressure steam generator, as no "boiling" actually occurs in this device.

- Hydronic boilers: Hydronic boilers are used in generating heat for residential and industrial purposes. They are the typical power plant for central heating systems fitted to houses in northern Europe (where they are commonly combined with domestic water heating), as opposed to the forced-air furnaces or wood burning stoves more common in North America. The hydronic boiler operates by way of heating water/fluid to a preset temperature (or sometimes in the case of single pipe systems, until it boils and turns to steam) and circulating that fluid throughout the home typically by way of radiators, baseboard heaters or through the floors. The fluid can be heated by any means...gas, wood, fuel oil, etc., but in built-up areas where piped gas is available, natural gas is currently the most economical and therefore the usual choice. The fluid is in an enclosed system and circulated throughout by means of a motorized pump. The name "boiler" can be a misnomer in that, except for systems using steam radiators, the water in a properly functioning hydronic boiler never actually boils. Some new systems are fitted with condensing boilers for greater efficiency. These boilers are referred to as condensing boilers because the boilers are designed to operate at lower temperatures than typical hydronic boilers. These lower temperatures would typically damage a boiler because it would cause condensation in the flue gases which ultimately form carbonic acid which corrodes the flue and fireside boiler heating surfaces. Condensing boilers solve this problem by routing the carbonic acid down the drain and by making the flue out of stainless steel or PVC. Although condensing boilers are becoming more popular, they are still less common than other types of hydronic boilers because they are more expensive.

Hydronic systems are being used more and more in new construction in North America for several reasons. Among the reasons are:

- They are more efficient and more economical than forced-air systems (although initial installation can be more expensive, because of the cost of the copper and aluminum).

- The baseboard copper pipes and aluminum fins take up less room and use less metal than the bulky steel ductwork required for forced-air systems.

- They provide more even, less fluctuating temperatures than forced-air systems. The copper baseboard pipes hold and release heat over a longer period of time than air does, so the furnace does not have to switch off and on as much. (Copper heats mostly through conduction and radiation, whereas forced-air heats mostly through forced convection. Air has much lower thermal conductivity and volumetric heat capacity than copper, so the conditioned space warms up and cools down more quickly than with hydronic. See also thermal mass.)

- They tend to not dry out the interior air as much as forced air systems, but this is not always true. When forced air duct systems are air-sealed properly, and have return-air paths back to the furnace (thus reducing pressure differentials and therefore air movement between inside and outside the house), this is not an issue.

- They do not introduce any dust, allergens, mold, or (in the case of a faulty heat exchanger) combustion byproducts into the living space.

- Forced-air heating does have some advantages, however. See forced-air heating.

- Boiler fittings and accessories:

+ Safety valve: It is used to relieve pressure and prevent possible explosion of a boiler.

+ Water level indicators: They show the operator the level of fluid in the boiler, also known as a sight glass, water gauge or water column is provided.

+ Bottom blowdown valves: They provide a means for removing solid particulates that condense and lie on the bottom of a boiler. As the name implies, this valve is usually located directly on the bottom of the boiler, and is occasionally opened to use the pressure in the boiler to push these particulates out.

+ Continuous blowdown valve: This allows a small quantity of water to escape continuously. Its purpose is to prevent the water in the boiler becoming saturated with dissolved salts. Saturation would lead to foaming and cause water droplets to be carried over with the steam - a condition known as priming. Blowdown is also often used to monitor the chemistry of the boiler water.

+ Flash Tank: High pressure blowdown enters this vessel where the steam can 'flash' safely and be used in a low-pressure system or be vented to atmosphere while the ambient pressure blowdown flows to drain.

+ Automatic Blowdown/Continuous Heat Recovery System: This system allows the boiler to blowdown only when makeup water is flowing to the boiler, thereby transferring the maximum amount of heat possible from the blowdown to the makeup water. No flash tank is generally needed as the blowdown discharged is close to the temperature of the makeup water.

+ Hand holes: They are steel plates installed in openings in "header" to allow for inspections & installation of tubes and inspection of internal surfaces.

+ Steam drum internals, A series of screen, scrubber & cans (cyclone separators).

+ Low- water cutoff : It is a mechanical means (usually a float switch) that is used to turn off the burner or shut off fuel to the boiler to prevent it from running once the water goes below a certain point. If a boiler is "dry-fired" (burned without water in it) it can cause rupture or catastrophic failure.

+ Surface blowdown line: It provides a means for removing foam or other lightweight non-condensible substances that tend to float on top of the water inside the boiler.

+ Circulating pump: It is designed to circulate water back to the boiler after it has expelled some of its heat.

+ Feedwater check valve or clack valve: A non-return stop valve in the feedwater line. This may be fitted to the side of the boiler, just below the water level, or to the top of the boiler.

+ Top feed: A check valve (clack valve) in the feedwater line, mounted on top of the boiler. It is intended to reduce the nuisance of limescale. It does not prevent limescale formation but causes the limescale to be precipitated in a powdery form which is easily washed out of the boiler.

+ Desuperheater tubes or bundles: A series of tubes or bundles of tubes in the water drum or the steam drum designed to cool superheated steam. Thus is to supply auxiliary equipment that does not need, or may be damaged by, dry steam.

+ Chemical injection line: A connection to add chemicals for controlling feedwater pH.

- Steam accessories

+ Main steam stop valve:

+ Steam traps:

+ Main steam stop/Check valve: It is used on multiple boiler installations.

- Combustion accessories

+ Fuel oil system:

+ Gas system:

+ Coal system:

+ Soot blower

- Other essential items:

+ Pressure gauges:

+Feed pumps:

+ Fusible plug:

+ Inspectors test pressure gauge attachment:

+ Name plate:

+ Registration plate:

- Controlling draught

Most boilers now depend on mechanical draught equipment rather than natural draught. This is because natural draught is subject to outside air conditions and temperature of flue gases leaving the furnace, as well as the chimney height. All these factors make proper draught hard to attain and therefore make mechanical draught equipment much more economical.

There are three types of mechanical draught:

+ Induced draught: This is obtained one of three ways, the first being the "stack effect" of a heated chimney, in which the flue gas is less dense than the ambient air surrounding the boiler. The denser column of ambient air forces combustion air into and through the boiler. The second method is through use of a steam jet. The steam jet oriented in the direction of flue gas flow induces flue gasses into the stack and allows for a greater flue gas velocity increasing the overall draught in the furnace.

This method was common on steam driven locomotives which could not have tall chimneys. The third method is by simply using an induced draught fan (ID fan) which removes flue gases from the furnace and forces the exhaust gas up the stack. Almost all induced draught furnaces operate with a slightly negative pressure.

+ Forced draught: Draught is obtained by forcing air into the furnace by means of a fan (FD fan) and ductwork. Air is often passed through an air heater; which, as the name suggests, heats the air going into the furnace in order to increase the overall efficiency of the boiler. Dampers are used to control the quantity of air admitted to the furnace. Forced draught furnaces usually have a positive pressure.

+ Balanced draught: Balanced draught is obtained through use of both induced and forced draught. This is more common with larger boilers where the flue gases have to travel a long distance through many boiler passes. The induced draught fan works in conjunction with the forced draught fan allowing the furnace pressure to be maintained slightly below atmospheric.

|

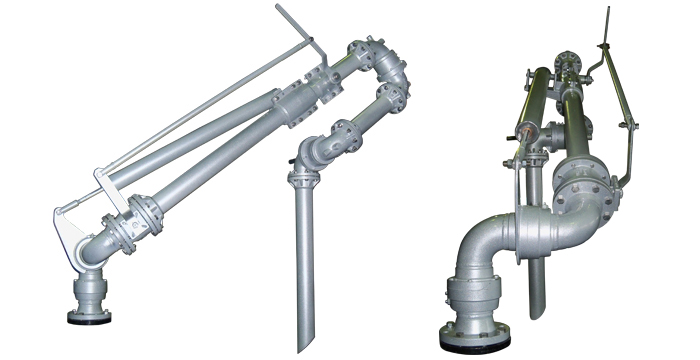

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu

![header=[Buffer tank, chiller tower, boiler tank] body=[<div align='justify' style='height:120px;'><img src='http://iva-vietnam.com/watemark.php?pic=buffer vessel_hot water boiler_chiller tower_plate heat exchanger_shell exchanger_tube exchanger.jpg' hspace = '10' align='left'></div>]](http://iva-vietnam.com/watemark.php?pic=buffer vessel_hot water boiler_chiller tower_plate heat exchanger_shell exchanger_tube exchanger.jpg)

![header=[Water cooled chiller system, Boiler system] body=[<div align='justify' style='height:120px;'><img src='http://iva-vietnam.com/watemark.php?pic=Cooling Tower Water Plate heat Exchanger.jpg' hspace = '10' align='left'></div>]](http://iva-vietnam.com/watemark.php?pic=Cooling Tower Water Plate heat Exchanger.jpg)