HA NOI — So few enterprises seem to understand the benefits of cleaner production in industry, the Government has approved a strategy to raise awareness with firms of the cost-savings and productivity gains that can be made from minimising environmental pollution.

The Cleaner Production in Industry Strategy by 2020 wants 50 per cent of industrial production establishments to be aware of the benefits that can be derived from applying cleaner production by 2015.

The figure is expected to increase to 90 per cent by 2020.

According to deputy director general of the Ministry of Industry and Trade (MoIT)’s Science and Technology Department Nguyen Huy Hoan, most enterprises still do not understand what cleaner production means.

Lack of information about cleaner production and limited financial resources are part of the reason.

Deputy director of the Ben Tre Sugar Joint Stock Company Le Van Tam admitted his company was totally ignorant about the concept until the Cleaner Production in Industry (CPI) strategy was spelt out.

The CPI is working with the company to evaluate existing technologies, while providing environmentally friendly alternatives, that will both avoid losses to sugar production, and prove less environmentally damaging.

Tam said his company did not have enough capital for the total investment in new technologies, but the CPI has offered to pay 50 per cent of the costs.

The assistance comes at a time when the company is looking for ways to avoid fines imposed by environment police. The company has already been fined for discharging untreated waste into the environment.

"The burden of how to stop polluting the environment puts a heavy weight on us," Tam said, "But it will become a thing of the past once the company applies cleaner production solutions."

Founded in 2006, the CPI is part of the Viet Nam-Denmark Development Co-operation in Environment programme under the MoIT’s chairmanship.

It has helped 44 enterprises in the five provinces of Phu Tho, Thai Nguyen, Quang Nam, Nghe An and Ben Tre apply cleaner production in industry.

Each enterprise represents a success story in cleaner production.

The Hong Ha Beer Factory in northern Phu Tho Province, had to use 12 litres of water to produce one litre of beer in the past. But after applying cleaner production methods the factory needs only 8 litres of water to produce a litre of beer.

"Cleaner production methods have enabled the factory to save raw materials and end up treating less waste water," head of the factory’s technical section Trinh Vu Duc explained.

Previously, about 300 cubic metres of waste water were discharged into a fish pond behind the factory. As the discharged water had a high organic content, it created a highly unpleasant smell and led to a dramatic decline in fish breeding productivity.

These troubles disappeared following the factory’s introduction of clean production at the end of 2007.

By applying low cost cleaner production solutions, the factory has been able to save costs in coal, electricity and water of VND313 million (US$17,388) every year. The company has spent just about VND12 million ($666) on a cleaner solution since then.

"The key to our success lies in the determination to change our way of thinking," Duc said, "Investment in equipment isn’t so high but the outcome earned from it is unpredictable."

Although the benefits are obvious, only a modest number of enterprises are applying cleaner production in industry, with numbers hovering at just 300 of a total 35,000 small- and medium-sized enterprises, according to the Viet Nam Cleaner Production Centre.

Most of them came up with cleaner production solutions only after receiving advice and financial support from outsider like the CPI.

The Government has not yet considered the provision of financial aid to help local enterprises apply cleaner production in industry as a top priority.

"So organisations like the CPI are very useful to help more enterprises like ours understand and apply cleaner production solutions," said Duc.

Component co-ordinator Nguyen Thi Lam Giang said many enterprises have spent a lots of money on waste treatment facilities, but it was merely a sticking-plaster solution.

She descibed cleaner production solutions as a tool to help enterprises achieve inter-linked advantages for the economy, the environment and society.

"The thing is, if they don’t apply cleaner production this year they have to do it in the following years because they can’t deal with the environment police for ever," Giang said.

Deputy director general of the Science and Technology Department Nguyen Huy Hoan also agreed that cleaner production was an optimal solution for enterprises in a situation where they lack the necessary funds to purchase advanced technology, raising productivity and environmental protection at the same time.

For these reasons, Hoan said the Cleaner Production in Industry Strategy by 2020 helped raise awareness among enterprises about the importance of cleaner production application.

Asked if it would be possible to realise targets outlined by the strategy, general director of the Viet Nam Cleaner Production Centre Tran Van Nhan said it might be feasible to help 50 per cent of industrial production establishments come to an understanding about cleaner industrial production by 2015.

"But it is uncertain whether all of them will apply cleaner production," Nhan added.

The strategy also wants to have 25 per cent of industrial production establishments applying cleaner production in industry by 2015.

As there are no laws forcing enterprises to apply cleaner production, Giang said, "it is merely based on their voluntarism."

The situation has resulted in a limited number of enterprises applying cleaner production although the concept took root in Viet Nam as early as 1998 when the Viet Nam Cleaner Production Centre was established under the sponsorship of the Swiss Government.

The problem is compounded by the meagre number of experts to promote the application of cleaner production in industry.

Nhan said there were less than 100 experts working in the field at present. Others had retired, or shifted to other jobs because of not being able to find customers.

Yet Nhan believes with the launch of the strategy, the first ever long-term document on cleaner production, many enterprises will consider cleaner production as a part of their production strategy in the near future. — VNS(19-09-2009)

by Hong Thuy

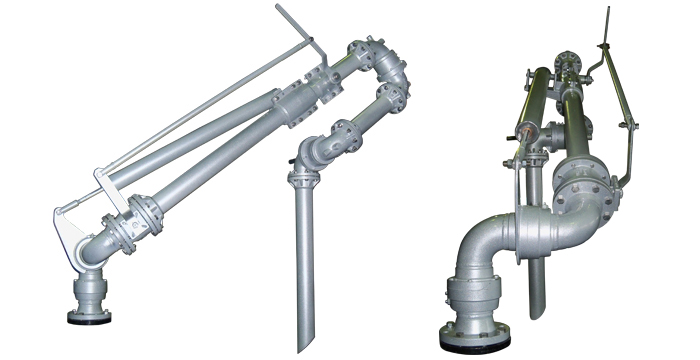

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu