|

Iva Vietnam is willing being the bigest supplier as well as the best distributor for worldwide famous brand names of all kind of industrial pumps, valves & engines in Vietnam market INDUSTRIAL STRAINERS :

*Basket strainer : Basket Strainers feature top removal of the screen. The screen is in the form of a basket, with a lifting handle, so that all particulate captured and retained by the screen can be easily removed for disposal. They are intended for applications where large amounts of solids particulate are expected and where the clean-out will be frequent. For easily flushable solids, a modified cone bottom basket can be tilted with automatic or manual blow-down through drain port. This will allow clean-out without removal of the screen, and without interrupting the flow process. Features include Large basket size holds sufficient solids for the required time between clean-outs, Top removal of screan with a lifting handle, Maintenance features includes Automatic flush, Davit arm assembly, pressure gaps or difficult pressure gaps, special internal coatings, single or multiple baskets, Baskets made of heavy guage perforated stainless steel lined with wire mesh as low as 5 microns.

- Basket Strainers range in size from 3/8” – 24” with Threaded, Socket Weld or Flanged End Connections. Pressure ratings are ANSI 125-600#. Standard body materials offered are Cast Iron, Ductile Iron, Cast Steel, Stainless Steel, Chrome-Moly and Bronze. Various Perforations, Mesh or Perforation Mesh combinations baskets are available to meet your process requirements. Basket Strainers can be equipped with Bolted Covers, Hinged Covers, Clamped Covers, a Davit Lifting Device or other Lifting Device to make removal of large heavy covers safe and efficient. Widespread list of options are available.

* Duplex Strainer : Duplex Strainers are designed for applications where flow cannot be shut down to service the strainer screen. Change over is accomplished by use of butterfly valves. This arrangement provides a bubble-tight shut off between basket chambers, essential for use in negative head pump suction systems. They are very economical because they are fabricated to your specific requirements and with your choice of valves.

* Y - Strainer: Y Strainers take their name from their configuration. They are typically used in application where the amount of solids to be removed is small, and where frequent clean - out is not required. They are most commonly used in pressurized lines, gas or liquid, but can also be used in suction or vacuum conditions. A Y-Strainer has the advantage of being able to be installed in either a horizontal or vertical position. However, in both cases, the screening element or "leg" must be on the "downside" of the strainer body so that entrapped solids can be properly collected and held for disposal. A blow down plug on the drain port will allow clean-out without removal of the screen, and without interrupting the process flow. Features include Machined, tapered seat ensures a perfect fit for removable, stainless steel screen, Covers furnished with blow off tapping, Heavy gauge perforated stainless steel normally furnished with spot welded seams. For exceptionally fine straining, perforated screens are lined with wire mesh.

- These types of strainers are named after their shape and normally used for course filtration. But with large filtration area can be used with fine mesh also. Body of Y strainer is normally of cast iron or cast steel in various grades with flanged and socket weld type end connection. Fabricated Y strainers are also available.

Features & Options:

- Easy cleaning or replacing the element.

- Compact size and Low weight

- Low Pressure drop across the filter.

- Low Installation and maintenance.

- With Drain Arrangement on request

- Adequate strength of element and housing

- Interchangeability of component with another of same type.

* Tee strainer is a custom fabricated compound strainer designed to remove foreign particles from pipeline.Tee Type Strainers are a low cost solution to large nominal bore straining requirements. They can be mounted into vertical or horizontal piping and can be configured for right-angled applications.

- Tee strainers are most commonly supplied with a range of graded filtration levels (fine to coarse or vice-versa) to ensure that the system is running at the required cleanliness level when met with full load. Tee strainers feature either bolted cover or quick opening covers for application suitability.

- Tee strainers are used where a compact accessible strainers is needed for protection of pumps, valves and similar equipment.

- We supplies temporary strainers in various styles (Baskets, Cones, Cone type baskets, Plate) which are designed to provide inexpensive protection for pumps, meters, valves and other mechanical equipments. Procedyne can customize baskets to fit your special needs.

- Our Engineers designs and fabricates various styles and types of strainers. Our products are designed and built with accordance to the highest industry standards.

* Fabricated Strainers can be designed to your specific application in almost any material. Basket size can be chosen to fit existing piping, or to achieve the required clean pressure drop. Maintenance reducing features include Automatic flush and Hinged cover, with or without davit assembly, to name a few.

* Automatic Self Cleaning Strainer is designed for continuous removal suspended particles from all type of liquids. Application are in industrial plants using river, lake well or sea water for cooling, descaling, bearing lubrication and similar purpose, pipeline size, 50 mm to 1200 mm or large upon application. Liquids other than water, such as chemicals acids white water (paper mills), sewage and ammonia flushing liquor can also be (coke plant) effectively strained.

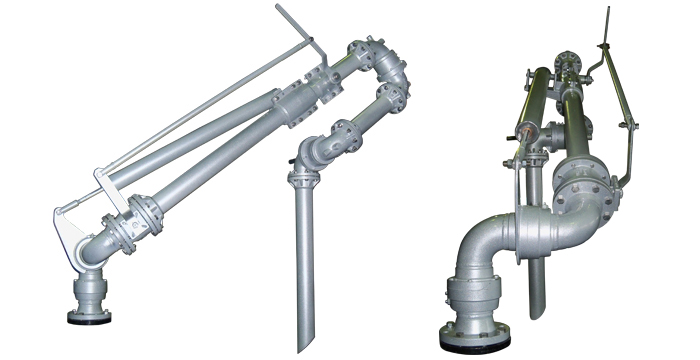

*Suction Diffuser: Suction diffusers mounts to the suction side of a pump in either a horizontal or vertical position.Suction Diffusers incorporate the functions of a strainer, flow straightener, elbow and pipe reducer in one compact unit thereby reducing installation costs. It is designed to remove any foreign matter that may be hazardous to the pump or other system components,while providing the proper flow conditions to the pump. Procedyne Suction Diffusers are available in cast iron configured to replace a standard 90° elbow as well as in fabricated carbon steel or stainless steel customized to suit your installation.

A wide variety of optional screens, mesh liners, covers, materials and other custom options are available.

*Air Eliminator: Air Eliminators and Combination Air Eliminator Strainers are designed to provide separation, elimination and prevention of air in piping systems for a variety of installations and conditions. Positive displacement and turbine meters, being volumetric measuring devices, cannot differentiate between liquid, air and vapor. Although the air content, in most instances, is small when compared with the product, it will contribute to measurable error. Large amounts of free air or vapor entrapped in a piping system, not only compromises meter accuracy but can lead to overspeeding of the measuring unit, creating excessive wear or possible unit failure. To insure accurate liquid measurement, it is necessary to remove all vapor and free all entrained air from the system prior to entry into the measuring unit.

- Air Eliminators decrease the velocity of the flowing stream and bring the liquid to a state of relative calm so that air bubbles or vapor will rise. As air and vapor collect in the top of the vessel, liquid volume is displaced.

* Automatic Scraper Strainer is a motorized unit designed for the continuous removal of suspended solids from intake, process and wastewater flows.

- These units can handle heavy solids loading with particles as small as 75 microns and as large as 150mm (6" stones). Our strainers have been installed on applications where backwash strainers have suffered premature clogging, such as black liquor, heavy oils, wax, unprotected river water intakes and boiler waste slurries.

- Cleaning is accomplished by a spring-loaded blade and brush system managed by a fully automatic control system. The blades remove larger solids while the brush clean out the individual slots of the wedgewire filtration element, removing smaller particles.The spring-loaded mechanism maintains blade and brush contact with the screen at all times.

- A separate blowdown timer allows the accumulated solids to be expelled from the bottom of the strainer vessel where they are collected during the scraping cycle. Having a separate blowdown cycle allows our scraper strainer to use far less fluid for cleaning than competing backwash designs.

- The Scraper strainers are available in sizes 2" through 36" in fabricated construction using carbon steel, stainless steel and assorted alloys. All strainer vessels are designed and built in general accordance with ANSI and ASME Sec. VIII, Div. 1. Nozzle arrangements can be offset (standard), in-line at the top and at the bottom of the vessel.

Typical Applications:

- Automatic Scraper Strainers are used in nearly every industry to strain river, lake or seawater intakes for plant cooling water, fire protection and process requirements.

- Process Industry - Protect heat exchangers, pumps, valves and water spray nozzles.

- Power Industry - Protect heat exchangers, pump seal water, boiler wash water nozzles.

- Pulp & Paper - White water and black liquor filtration.

- Wastewater Treatment - Straining secondary effluent to protect spray nozzles and provide plant service water.

- Metal and Mining Industries - Provide clean water for quenching, de-scaling, blast furnace cooling.

* Baskets And Custom Screens: We offer replacement screens and baskets and temporary strainers not only for our own products but for those of our competitors as well. Basket, Cone, Plate, Reverse Flow and many different engineering designs are available.

We specialize in supplying standard replacement strainer screens and baskets as well as custom engineered designs or competitor units. Often a screen or basket failure could mean a wrong unit is being used. Our knowledgeable staff will ask the right questions to ensure the correct replacements are being supplied. Provide us with a drawing and we will design and supply to your requirements.

|

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu