|

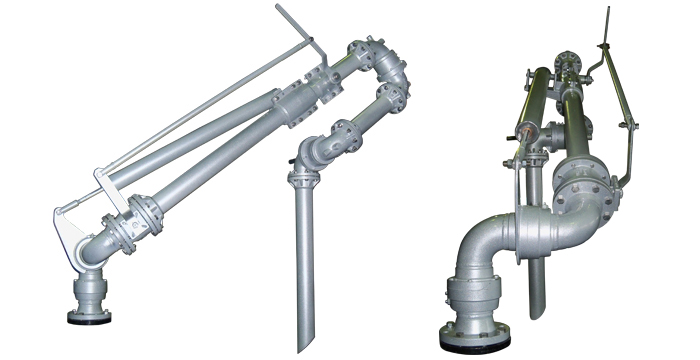

The Vertical Turbine Pumps have three main parts: the head assembly, column assembly and the pump bowl assembly.

The shaft and column assembly provides a connection between the head and pump bowls. The line shaft transfers the power from the motor to the impellers and the column carries the water to the surface. The line shaft on a turbine pump may be either water lubricated or oil lubricated.

- Vertical turbine pumps for fire fighting, irrigation, dewatering, and water lift pumps for your industrial and municipal applications...

- The vertical turbine pump (sometimes call line-shaft turbine pump) with centrifugal type impeller, mixed flow type impeller or axia-flow type impeller.

- The vertical turbine pump could be driven by standard vertical motor or driven by horizontal driver (electric motor, diesel engine) by the right angle gear box. The underground column and shaft is devided into several sections, So, the vertical turbine pump is very flexible to get the desired length to meet the deepth of the well. The vertical turbine pump can offer any tailor maded according to the project request. The vertical turbine pump is completely according to any application and performance request.

Main design ficgures of Vertical turbine pump, Vertical turbine fire pump :

+ Open or enclosed lineshaft construction

+ Enclosed or semi-open impellers, keyed or collet mounted

+ Bowl and enclosed impeller wear rings

+ Cast iron or fabricated steel discharge heads

+ Sealing configurations for open lineshaft construction

- Packed box with flexible graphite packing

- Single or dual mechanical seal

Sealing configurations for enclosed lineshaft construction

- Enclosing tube tension assembly for oil lubrication

- Water injection packing assembly

Above ground or below ground discharge flanges

Multiple drivers:

- Electric motors, solid or hollow shaft

- Engines with right angle gear drives

- Steam turbines

Separate axial thrust bearing assembly

Standard and ISO 13709/API 610 (VS1), UL listed, FM approval, NFPA-20 latest edition configurations

Operating Parameters:

- Flows to 27 000 m3/h ~97 000 m3/hr (425 000 gpm)

- Heads to 700 m (2300 ft)

- Pressures to 100 bar (1450 psi)

- Temperatures from -45°C (-50°F) to 300°C (570°F)

- Sizes from 100 mm (4 in) to 1375 mm (55 in)

- Settings to 365 m (1200 ft)

Applications:

Flood Control, Drilling and Production, FPSO, Geothermal Well Services, Ground Water Development and Irrigation, LNG, Agriculture, Nuclear Service, Snowmaking, Offsites and Waste Treatment, Renewable Fuel Production, Shipping, Transformer Cooling, Water Treatment, Auxiliary (chemical), Water Supply and Distribution (water), Auxiliary Services (power), Cooling Water (metals), Cooling Water (power), Dewatering and Water Supply (mining)

Industries: General Industries, Mining, Oil and Gas, Chemical Processing, Primary Metals, Water Resources, Power Generation

Vertical turbine pumps are available in a wide variety of configurations, constructions and materials to suit application requirements.

|

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu

![header=[Automatic booster pump system with inverter control, Inverter booster pump ] body=[<div align='justify' style='height:200px;'><img src='http://iva-vietnam.com/watemark.php?pic=Inverter-booster- pump-water-boosting-pump-with-inverter-control.jpg' width=200px hspace = '10' align='left'></div>]](http://iva-vietnam.com/watemark.php?pic=Inverter-booster- pump-water-boosting-pump-with-inverter-control.jpg)

![header=[Vertical Sump pump, Vertical drain pump, Vertical slurry pump, Vertical immersion pump] body=[<div align='justify' style='height:200px;'><img src='http://iva-vietnam.com/watemark.php?pic=vertical_drain_pump_vertical_immersion_pump_vertical_sump_pump_vertical_slurry_pump_iva_vina_vietnam_pump.jpg' width=200px hspace = '10' align='left'></div>]](http://iva-vietnam.com/watemark.php?pic=vertical_drain_pump_vertical_immersion_pump_vertical_sump_pump_vertical_slurry_pump_iva_vina_vietnam_pump.jpg)

![header=[Vertical Multistage Pump, Booster pump, Vertical Centrifugal Pump] body=[<div align='justify' style='height:200px;'><img src='http://iva-vietnam.com/watemark.php?pic=Jockey_pump_vietnam_boosting_pump_vertical_multistage_pump_bom_truc_dung.jpg' width=200px hspace = '10' align='left'></div>]](http://iva-vietnam.com/watemark.php?pic=Jockey_pump_vietnam_boosting_pump_vertical_multistage_pump_bom_truc_dung.jpg)