|

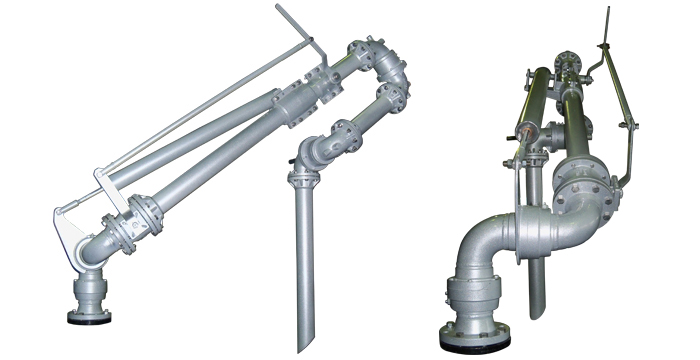

When deciding upon a conceptual design for road and rail tanker loading stations some basic principles need to be considered. Top loading arm , and Bottom loading arm each have their own advantages, which can benefit the installation when correctly applied. Features and benefits of both Top loading arm, and Bottom loading arm are provided in later sections detailing these products more fully.

In general terms, however, the basic design data needed for a loading station includes the following, all of which may not be applicable in every case.

Design data may include:

- Type of fluid; temperature, pressure

- Viscosity in normal/abnormal condition

- Capacity in m3 or tonnes/hour

- Multi-product loading

- Number of different fluid media at one loading station

- Number of loading arms filling simultaneously at one tanker

- Required level of operator safety

- Environmental requirements; i.e. vapour return/recovery overspill protection

Integration with metering or weighbridge facilities

The following is applicable irrespective of whether top or bottom loading, or even a combination of both is specified.

A common requirements for all fluid transfer systems is that contact with man and environment should be avoided. This demands no leakages, no-spill connect/disconnect, self draining systems, lockable stored position, etc.

Hundreds of user friendly and easy to operate KANON loading systems are in use today in highly demanding applications.

This brochure provides the tools to enable the correct solution to be selected.

BALANCING

Loading arms should be balanced such that minimum weight is borne by the operator irrespective of the position of the arm.

Balancing starts with the loading arm design; forces working on one end of the arm are to be compensated for by traditional counterweight, or more advanced spring balancing, at the other.

The maintenance free balance cylinder is designed for applications which demand less space and can be combined with hydraulic or pneumatic operation.

The spring cylinders with multiple compression spring packages, can be adjusted to meet changes in operating conditions. Compared with conventional designs, The adjustable spring cylinders excel in terms of safety and long life.

BASIC CHARACTERISTICS

Sizes diameter: 1”, 2”, 3”, 4” and 6”

Materials: carbon steel, stainless, duplex, low temperature steel, Hasteloy, titanium and other special alloys, and with or without linings of rubber, PTFE or other materials.

Temperature range: -200º C +300º C.

Pressure range: maximum 120 bar.

Balancing: counterweight or spring cylinder. Seals: PTFE, viton, buna-N, perbunan and other on request.

TYPICAL PRODUCTS BY INDUSTRY SECTOR

Chemical

Phosphoric-, sulphuric-, nitric-, hydrochloric acids.

HF, HBr, vinyl chloride, MDI.

Caustic soda.

Ammonia.

Cryogenic applications such as: nitrogen (-196º C), oxygen (-183º C), Ethylene (-104º C).

Petrochemical

All hydrocarbons

Crude oil

LPG, butane, propane etc.

Bitumen

Sulphur

Phenol

Food

Vegetable oils

Fruit juices

Chocolate

Sauces

Soups

Raw Materials

|

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu