|

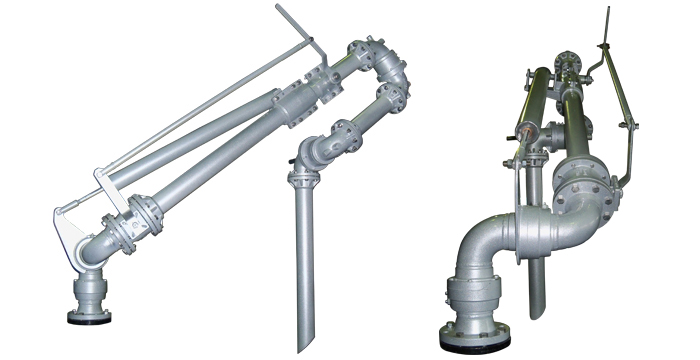

Multistage centrifugal pump, high pressure booster pumps are designed for trouble-free pumping for clear or slightly dirty liquids and used in: heating plants, waterworks and water supply plants, pressure raising plants, water and condensate circulation, fire fighting system, boiler feeding plants, high pressure washing, reverse osmosis. The horizontal multi-stage pump, high pressure booster pumps are multistage centrifugal with radial split casings. In all versions the supporting feet on pressure side are placed under the discharge body. For sizes up to 65 the base feet, on suction side, are placed under the first stage casing, to allow the rotation of the suction body in whatever direction. For bigger sizes the base feet are placed under the suction body, the rotation of which is possible only upon request. The impellers are provided with balancing holes to reduce the axial thrust. The shaft is supported by grease or oil lubricated roller bearings.

Standard execution temperature: up to 120°C

With cooling chamber: up to 160°C

NOTE: for temperatures exceeding 160°C please contact our Technical Department.

MAXIMUM OPERATING PRESSURE

On suction side: up to 25 bar

On discharge side: up to 100 bar

NOTE: for higher operating pressures, please contact our Technical Department.

TECHNICAL FEATURES

Capacity up to 1600 m3/h

Total head up to 650 m

Revolutions up to 3600 RPM

Pressure up to 64 bar

Flanges: suction side PN 16-25, delivery side PN 40-64

|

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu

![header=[API 610 - OH2 centrifugal pump, ASME B73.1 process pump for petroleum products transfer, ] body=[<div align='justify' style='height:200px;'><img src='http://iva-vietnam.com/watemark.php?pic=ansi-api-centrifugal-pump-may-bom-li-tam-bom-xang-dau-ansi-api-iva-vietnam.jpg' width=200px hspace = '10' align='left'></div>]](http://iva-vietnam.com/watemark.php?pic=ansi-api-centrifugal-pump-may-bom-li-tam-bom-xang-dau-ansi-api-iva-vietnam.jpg)

![header=[Axial Split casing pump, Single Stage case pump, Double Suction Centrifugal Pump] body=[<div align='justify' style='height:120px;'><img src='http://iva-vietnam.com/watemark.php?pic=Split case.gif' hspace = '10' align='left'></div>]](http://iva-vietnam.com/watemark.php?pic=Split case.gif)

![header=[Horizontal Centrifugal Pump : Closed coupled pump, in-line pump, multistage pump, End suction pump] body=[<div align='justify' style='height:200px;'><img src='http://iva-vietnam.com/watemark.php?pic=End suction pump IT.jpg' width=200px hspace = '10' align='left'></div>]](http://iva-vietnam.com/watemark.php?pic=End suction pump IT.jpg)