| |

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu |

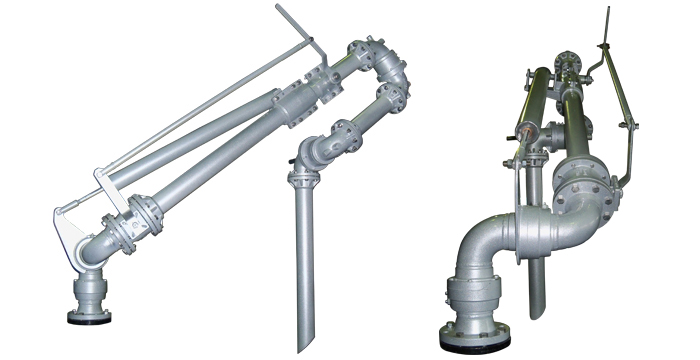

Hướng dẫn lựa chọn hệ thống định lượng xăng dầu, cần xuất dầu

Hướng dẫn lựa chọn hệ thống định lượng xăng dầu, cần xuất dầu |

Tư vấn lựa chọn, sử dụng đồng hồ đo lưu lượng, lưu lượng kế đo nước, đo xăng dầu và đo chất lỏng

Tư vấn lựa chọn, sử dụng đồng hồ đo lưu lượng, lưu lượng kế đo nước, đo xăng dầu và đo chất lỏng |

Hướng dẫn lựa chọn Barrier tự động, bãi đỗ xe tự động

Hướng dẫn lựa chọn Barrier tự động, bãi đỗ xe tự động |

Tư vấn, thiết kế hệ thống chữa cháy, hệ thống báo cháy tựu động, hệ thống sprinkler tự động TCVN

Tư vấn, thiết kế hệ thống chữa cháy, hệ thống báo cháy tựu động, hệ thống sprinkler tự động TCVN |

Bí quyết thông thạo các điều kiện Incoterm 2010 trong thương mại quốc tế

Bí quyết thông thạo các điều kiện Incoterm 2010 trong thương mại quốc tế |

|

| |

| |

Khách trực tuyến: 22 Khách trực tuyến: 22 |

Lượt truy cập: 6312 Lượt truy cập: 6312 |

|

| |

|

Frequently Asked Questions refer to Air operated double diaphragm pump in Vietnam

| Frequently Asked Questions refer to Air operated double diaphragm pump in Vietnam |

Frequently Asked Questions refer to Air operated double diaphragm pump in Vietnam

- Can I pump inks with this type of pump? (Similar questions are asked concerning paints and adhesives and can be answered in a similar manner)

ANSWER: Of course, but prior to making a pump selection you need to know if the fluid is a solvent or water-based product. What is the viscosity and temperature of the product? Generally if the fluid is solvent based a good choice is nylon or aluminum with PTFE elastomers (RD or AL/T) models. When pumping chlorinated solvents, KN (PVDF) models are the best choice.

- If the fluid temperature exceeds 150°F what pump should be used?

ANSWER: Pumps that are rated up to 200°F are the PVDF models and all of the metal pumps. Check your chemical compatibility chart for compatibility.

- When I cannot find a certain chemical on the resistance chart, what do I do?

ANSWER:

A. Ask what materials are presently being used to transfer the fluid or if there is a manufacturer’s recommendation that is on the fluid container, etc.

B. If there is no other information on this chemical, you will have to check with the manufacturer of the fluid and find out what is recommended.

C. Never guess at fluid to material combinations that are not substantiated.

- What if the chemical to material has a ‘B’ rating in the chemical resistance chart?

ANSWER: We do not recommend that anything other ‘A’ rated combinations are used. If you select a chemical to material rating of B the warranty is void. The pump may have serious problems and then again, there may be no problems.

- Can I use polypropylene with Hydrofluoric Acid?

ANSWER: Yes and No. The 1˝ and larger polypropylene models are fiberglass reinforced and CANNOT be used with hydrofluoric acid. The 1/4˝ and 1/2˝ models are pure polypropylene and can safely be used with hydrofluoric acid. 1˝ bolted plastic pumps are pure polypropylene and may also be used for Hf.

- What if the concentration of acid is given with a degree symbol, such as, 66°, does this mean that it is 66%?

ANSWER: The degree symbol means degrees baume. In this case the 66° is actually 98% in strength. You will find this symbol oftentimes used when describing sulfuric acid.

- Is there a model recommended for use in food applications?

ANSWER: The PVDF model is ultra pure and the material has the FDA 3A dairy rating and is often used for transferring sauces, flavorings, etc. Also, the stainless steel models are often used in these types of applications. You can have tri-clover fittings added to the stainless steel pumps. Check with the factory.

- Is there anything special that I should tell the customer when pumping hazardous fluids?

ANSWER: Yes. If a diaphragm should rupture, the exhaust should always be piped to a control area — a place for safe handling or back to the tank — since fluid will enter the air system if the diaphragm is breached. Leak detectors are available through the factory. Also, never forget to wear protection for eyes, lungs and skin when near hazardous fluids.

- Competitive pump companies recommend the use of an air line lubricator for continuous duty or intermittent usage. Do I need an air line lubricator for these pumps?

ANSWER: No, never use air line lubrication.

- Do we have a diaphragm material that is similar to Wilflex or Exel materials?

ANSWER: Santoprene is a competitive diaphragm material. It is similar to EPDM.

- I hear a lot about Geolast. What type of resistance does Geolast have?

ANSWER: It is similar to that of Buna-N (nitrile). Non-aggressive fluids only,

- My polypropylene pump is installed outside and has started cracking, what is the problem?

ANSWER: Polypropylene is not resistant to UV rays. Also, polypropylene is limited to use in temperatures over 32°F. For this type of application it is best to use a PVDF model, a metal model or shroud and insulate your polypropylene model.

- Can I operate the pumps at pressures higher than the maximum pressure ratings?

ANSWER: No, the pumps will start leaking, diaphragms may bulge and inner plates may bend.

- How should I regulate the flow of a diaphragm pump?

ANSWER: You can regulate the flow of a diaphragm pump three ways. Reduce or increase the air pressure, making sure that you are within the operating limits of the pump. You can increase or decrease the amount of air volume going to the pump via a valve on the air line and finally a valve on the fluid discharge may be opened or closed. NEVER restrict fluid suction lines!

- Can I submerge the pump?

ANSWER: Yes, if the fluid is compatible with the pump housing and fasteners and if you pipe the exhaust above the level of the fluid.

- Is there some way that I can extend the life of my diaphragms, balls and valve seats?

ANSWER: Remove sharp particles from the fluid. If the fluid is abrasive, slow the pumping speed or go to a larger pump. Do not over pressurize. In general, the slower the pump operates the longer life you will have with all moving components.

- The pump was working just fine, but it has slowed down and I’m not getting the needed capacity. What can I do?

ANSWER: Check fluid suction lines for obstructions and also check the valve seats for debris. Make sure that the fluid has not gotten more viscous with a decrease in the temperature.

- How do I pump high viscosity fluids?

ANSWER: If it pours, you can pump it.

A. Use large suction lines, up to three times the size of the pump ports.

B. Position the pump as close to (or below) the level of the fluid as possible.

C. Start the fluid slowly using a air line valve. Set the air pressure and crack the valve open slowly.

- I am seeing different suction lifts with different models, why?

ANSWER: Pumps built with PTFE balls have 10’ of suction lift. Pumps built with rubber or elastomeric balls have up to 15’ of suction lift. Pumps built with elastomeric valve seats also have higher suction lifts.

- Do all pumps have dual manifold capability?

ANSWER: All of the 1/2˝ clamped models have dual capability. The 1˝ plastic clamped models have dual manifolds capability and the 1/4˝ models can be configured at the factory with dual manifolds.

- How does high specific gravity effect my pumping application?

ANSWER: If the pump is flooded, fluids with high specific gravity may exceed the pump suction limitations of 10psi. If the pump is above the level of the fluid, high specific gravity will limit suction lift.

- Do I have to ground the pump when pumping flammable fluids?

ANSWER: Yes. This can be done with conductive plastic pumps via the grounding lugs. If you are not using a conductive plastic pump then ground the fluid through a metallic pipe nipple at both the suction and discharge ports. Metal pumps should also be grounded.

- How often should I tighten fasteners on my plastic pumps?

ANSWER: That depends on the application. Pressure, average hours in service, temperature all effect the flow of plastic. Pumps need tightening if leakage should occur. Tightening should be part of any preventive maintenance program and should be based on the service duty of the pump.

- What if I mix several chemicals together, can I use the individual material to chemical ratings that are listed in the chemical resistance chart to transfer this fluid mixtures?

ANSWER: Proceed with caution. Individual ratings may or may not be appropriate for a chemical cocktail. Again, is the fluid currently being transferred successfully using a particular set of materials?

|

| |

|

| Hotline:

0989.886.889 |

| Bán hàng Online (Mr Tuân) |

| Bán hàng Online (Ms Xuân) |

| Bán hàng Online (Mr Tú) |

| Bán hàng Online (Ms Thủy) |

| Bán hàng Online (Mr Huy) |

| Chăm sóc khách hàng (After Sales) |

| Admin: tu.hm@vietnam-pump.com |

| |

| |

|

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu

Hướng dẫn mua, sử dụng máy bơm công nghiệp, bơm cứu hỏa, bơm xăng dầu